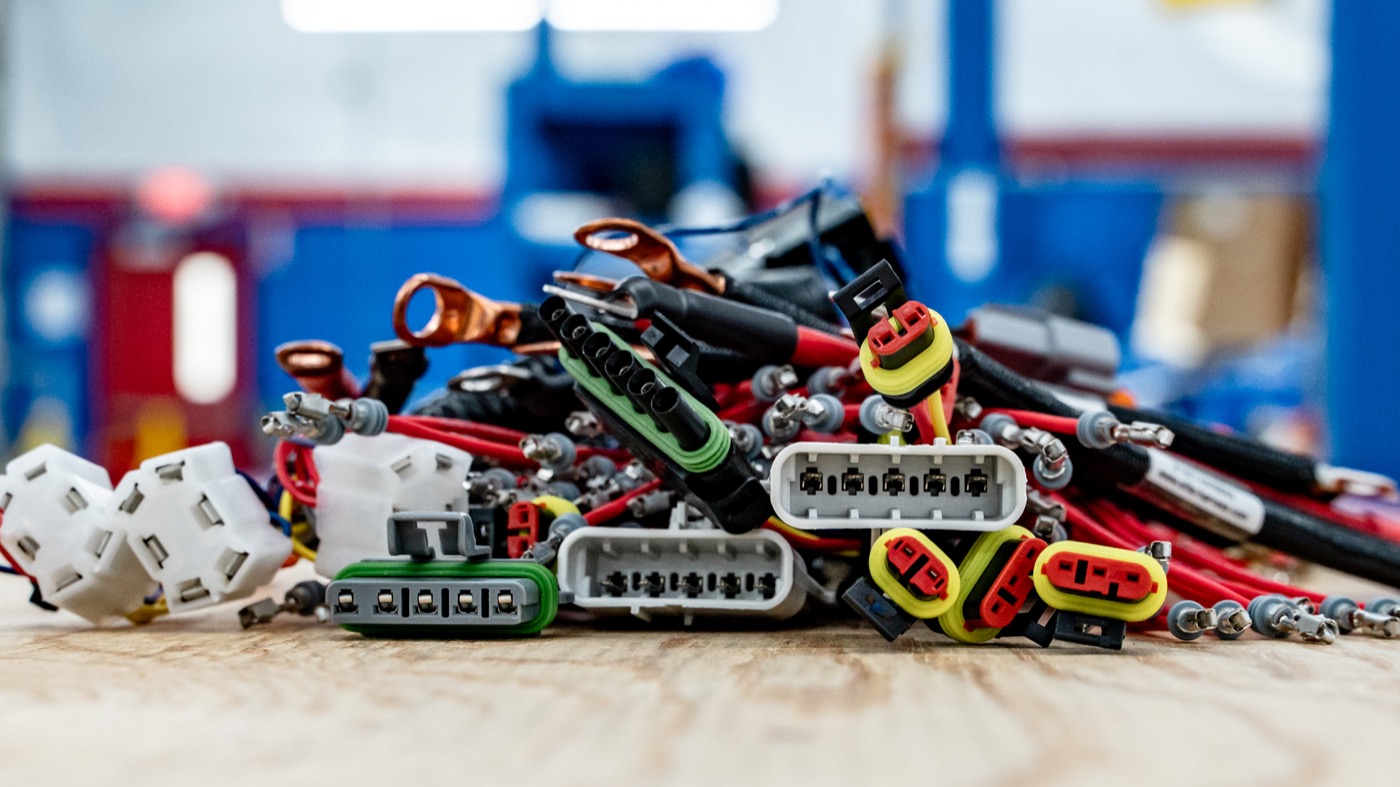

At Elite Harness, we pride ourselves on cultivating a collaborative, team-focused environment for our employees. We are committed to providing high-quality wire harnesses and battery cables to customers across a range of industries, including heavy industry, agriculture, aerospace, military and defense, turf management, transportation and beyond. Our facility is perfectly suited to manufacture for a wide variety of customer needs. From single-wire assemblies to complicated, multi-breakout harnesses, we have you covered. We manufacture all types of battery cables from short, small cables to long, heavy duty cables. We are equipped to run low-mix, high-volume and high-mix, low-volume runs. Our ability to change and adapt allows us to serve a wide range of customers both large and small.

The Industry’s Best Equipment

All of our machines at Elite are the most advanced equipment in our industry. While technology powers us, it is our people who drive us. This partnership guarantees optimal efficiency and exceptional quality.

- Sonic Welders to ensure the most secure wire-to-wire connections

- Braiding Machines quickly apply nylon braid which covers your harness or cable to prevent scuffing and provides protection from the elements.

- Wire Printers help our customers identify each wire

- Cut, Strip and Terminate Machines guarantee each wire is cut accurately while seals and terminals are secured perfectly

- Heavy Duty Cable Cut & Strip Machines

- Benchtop Lug Presses & Wire Termination Equipment guarantees perfect crimps and ensures durability and reliability.

- The Komax Zeta 650 is our 32-wire, fully automated cut, strip and termination machine. This equipment also has the ability to print on wire and provides bundling options which makes short work of multi-wire harnesses.